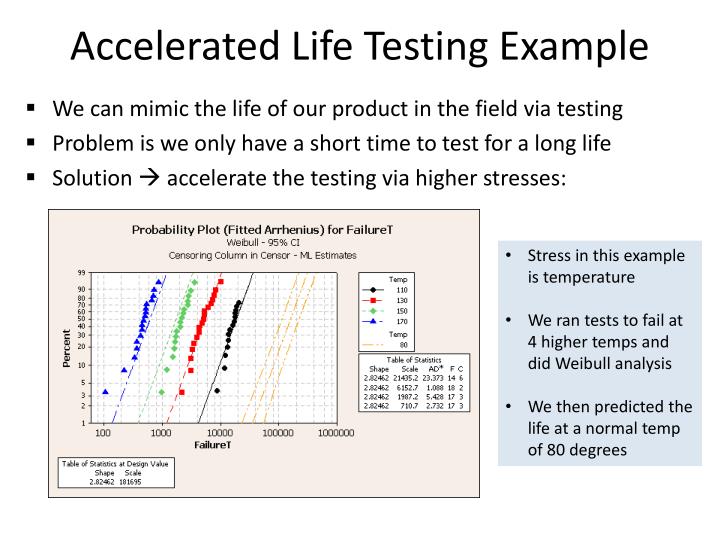

Accelerated life testing (ALT) is a type of testing used to predict the reliability and lifetime of a product within a shorter period of time. The purpose of this testing is to subject a device or product to extreme conditions in order to determine its ability to withstand harsh environments, and to determine its useful life expectancy. The popularity of the model is attributed to its ability to speeding-up time.

This model is mostly applied in cases when one cannot afford to wait for the occurrence of the failures at the normal course but would like to account for future occurrences of failure in the future times. It is also defined as a set of methods intended to ensure product reliability during design and manufacture in which stress is applied to promote failure. The applied stresses might be temperature, vibration, shock etc. In order to make a valid inference about the normal lifetime of the system from the accelerated data, by making time to failure short implicitly. It is necessary to know the relationship between time to failure and applied stress. Often parametric statistical models of the time to failure and of the manner in which stress accelerates ageing are used.

Uses of Accelerated Life Testing

ALT testing is considered highly useful in finding the effectiveness of derating, which is defined as a process that reduces a load of current on a component, lower than the rated load. It can also indicate the selection of a component that is rated more than the design load. It thus helps to determine the extent by which the life of a component can be extended, by computing the life-stress modelling. This type of testing is particularly useful for products that have a high life expectancy or are expected to experience a wide range of conditions during their operational lifetime. During accelerated life testing, the product is typically subjected to extreme conditions such as high temperature, high humidity, high voltage, or high pressure in order to simulate the product’s lifespan. This testing process forces the product to fail at a much faster rate than if it were simply used under normal conditions. The product is then monitored to observe how it performs under extreme conditions, and data is collected to determine its life expectancy.

Benefits

One of the biggest benefits of using accelerated life testing is the ability to identify potential design flaws or weaknesses in a product before it is released to the market. By testing the product under extreme conditions, engineers can identify potential issues that may arise during the product’s lifespan, and make design changes to improve the product’s reliability. This can save companies significant amounts of money in product recalls or warranty repairs, as well as increase customer satisfaction and brand loyalty.

Conclusion

In conclusion, accelerated life testing is an important part of product design and development, and is used to ensure that products are reliable and perform well under a range of conditions. By subjecting products to extreme conditions, engineers can identify potential issues and make design changes to improve product reliability and longevity, ultimately saving companies time and money.